Spezialist in Messing

Specialist in brass

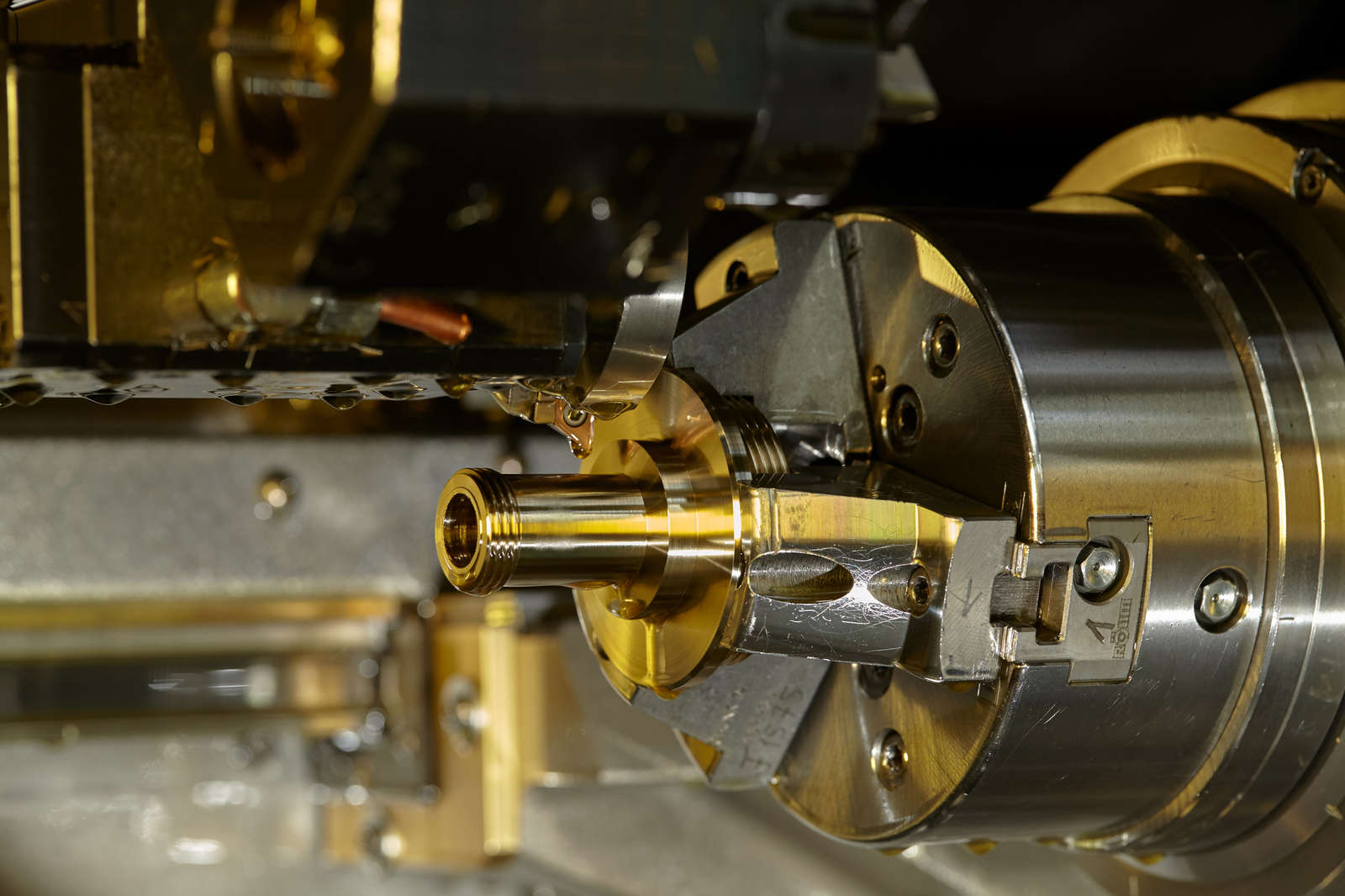

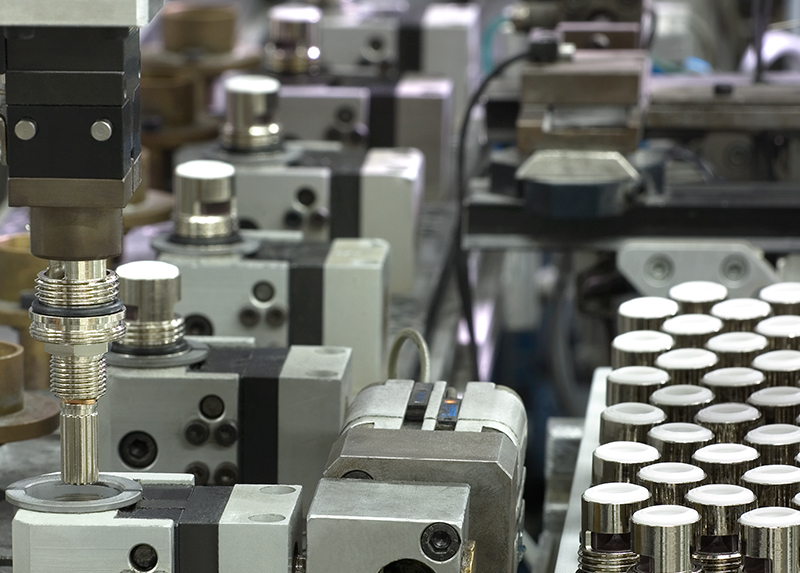

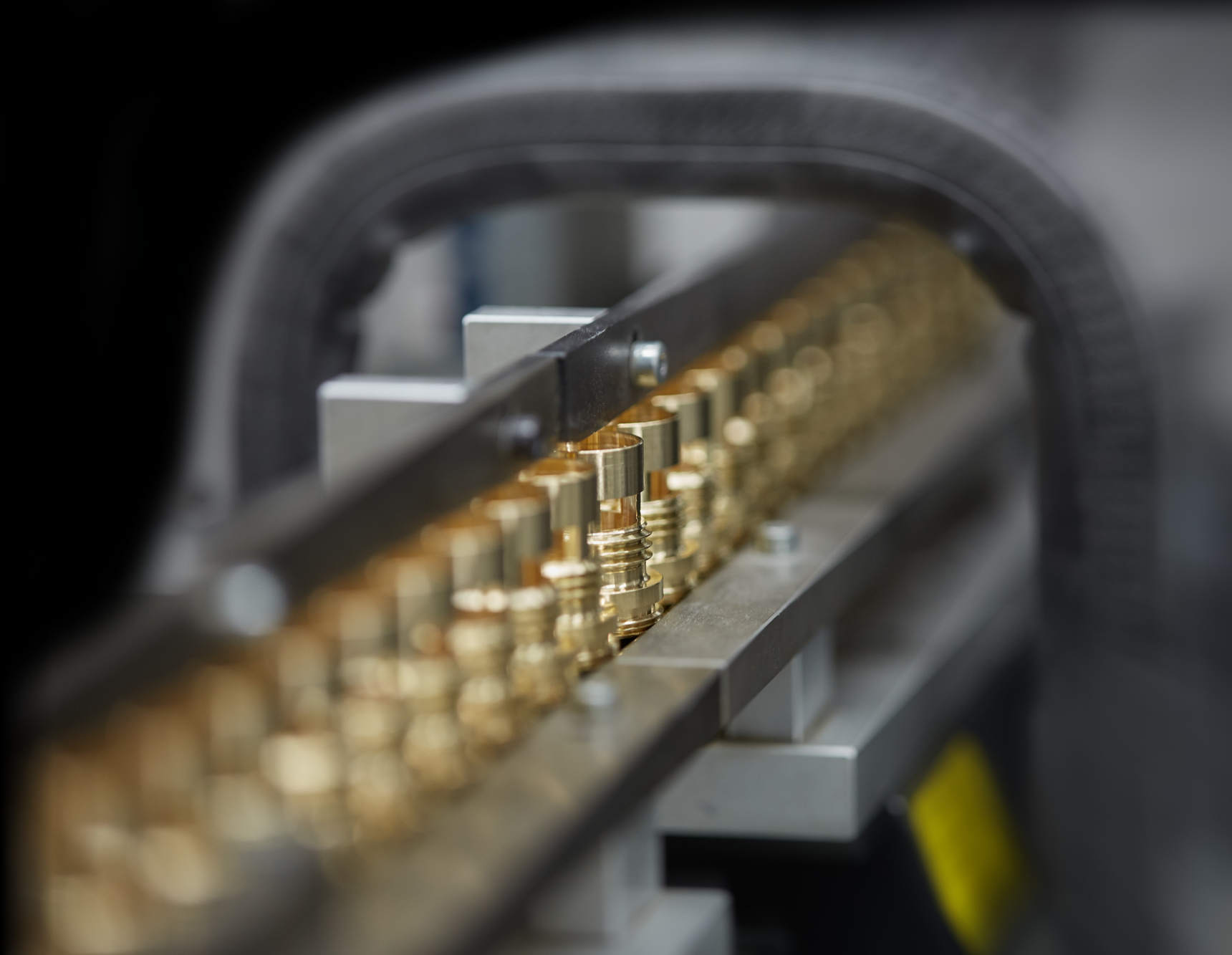

We are specialists in the use of brass, and our production programme ranges from the manufacture of simple turned parts to the complete processing of sophisticated products which satisfy customers individual requirements.

Our modern machinery and equipment ensure efficient manufacturing. The large number of machines guarantees the necessary production capacity to achieve fast, economical results.

We Manage Water

In Tradition leben (Kopie) (Kopie)

New ways in product design –

with us you discover new solutions you never thought possible

As an innovative supplier of complete systems Flühs Drehtechnik GmbH is one of the leading OEM suppliers of valve technology in the area of sanitary faucets and building technology. For generations, we have had a great deal of influence on the evolution in these market segments. The requirements in these areas of application, however, grow constantly and disproportionally high. On that account: Let’s manage water together.

Tradition

Tradition

Even in this globally digital world, we retain the values and standards which we have acquired over so many decades.

In Tradition leben

Living in tradition

We continue to place our faith in Germany as this is where our roots are, and it is home to our employees.

Customer-orientation is a growing company culture for us, one that we are continuing to develop.

Historie

History

Otto Flühs, then a 40-year-old set-up engineer for automatic lathes, founded the company in 1926. The economic conditions at the time were as bad as they could ever have been. Erich, his son, also started to work in the firm in the same year. After his father's death, it was Erich who took over the company and gave it its distinctive style.

Eine bewegte Geschichte

A colorful Story

As early as 1935 it became possible to purchase the buildings which had previously been rented at the current site in Lüdenscheid Brügge.

The company enjoyed healthy growth until 1939, with the number of workers increasing from the original 4 to 15.

Even in those early days, the main material which was turned was brass, in particular for the faucet industry.

After the end of World War II, production began again in May 1945. Once again operations started with 4 employees, just as they had done in 1926.

By 1948, sixteen people were working for the company, and the first multi-spindle machine was purchased.

By 1951, at the start of the German economic miracle, the company had 55 employees.

Extensive building work started in the mid-fifties, eventually leading to a production area of more than 20,000 m² in the new millennium.

The work force increased to over 400 employees.

Ahead of the curve…

The large number of machines ensures the production capacity which is necessary to achieve fast, economic results.

The material used in manufacturing, of up to 1,400 tonnes of brass rods, tubes and profiles, is purchased exclusively from semi-finished products suppliers who provide the high standard of quality material which we insist on.

The high-bay warehouse supplies the production department with the material required, so making maximum flexibility possible.

Materiallager

Werkzeugbau

Tool manufacturing department

One of the bases for Flühs quality, which is well-known around the world, is the comprehensive in-house tool manufacturing department.

The large number of experienced toolmakers, working with modern CNC turning, erosion and grinding machines, guarantee exact-fitting tools.

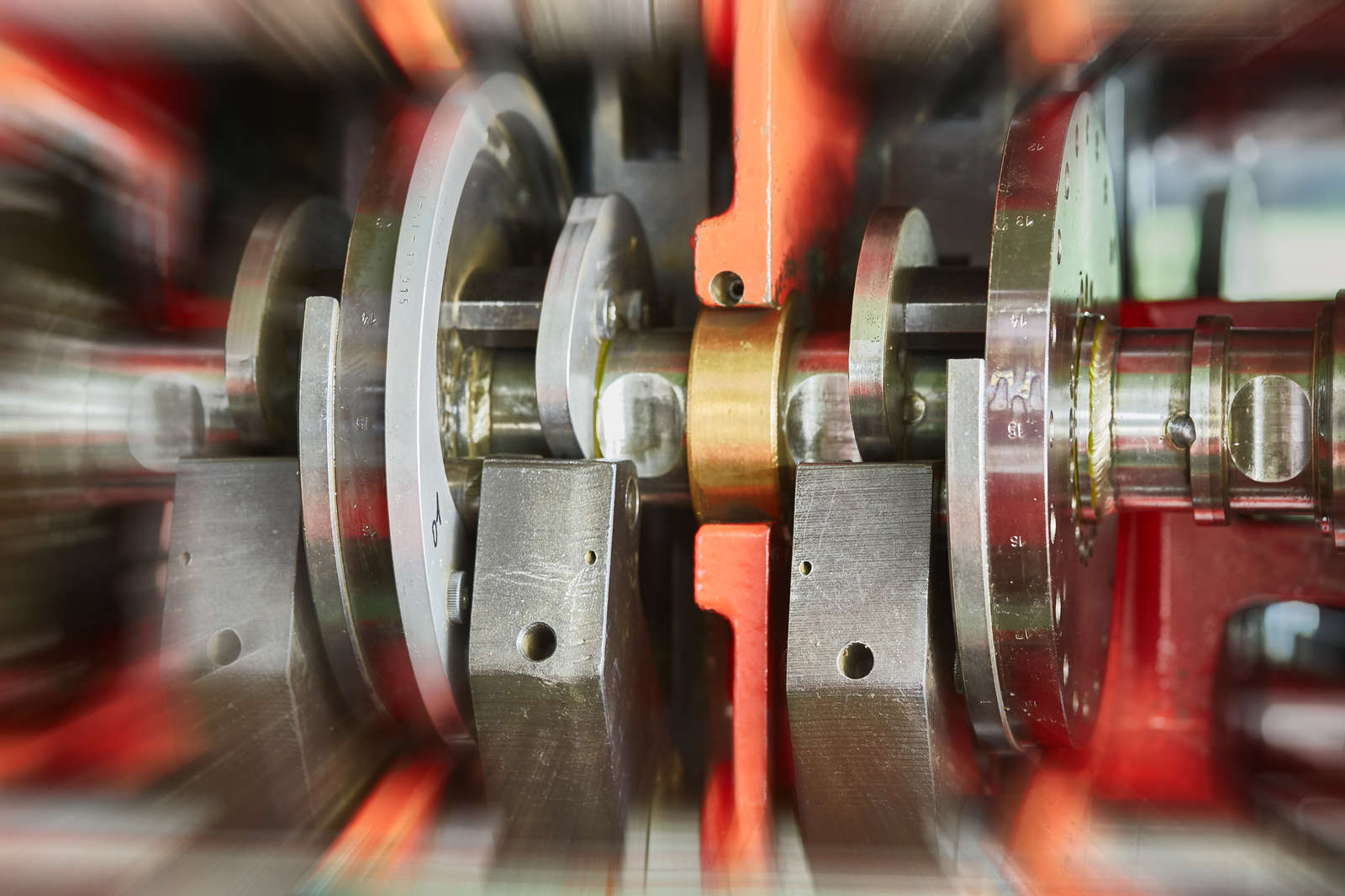

Drehautomaten

Automatic lathes

Flühs Drehtechnik's machines are optimally matched to each other and to the production requirements.

From zero series to large-scale production, the most up-to-date mechanical and CNC-controlled single and multi-spindle machines manufacture high-precision turned parts.

We have fully-automatic CNC lathe centres to carry out comprehensive processing operations.

Montage

Umwelt

Environment

A vision of economy in practice characterises the daily routine at Flühs Drehtechnik. Our very own patented separating process for cutting oil and solvent was awarded an environmental protection prize.

We are always mindful of tomorrow

The company's measures taken to ensure effective environmental protection include energy consumption, air quality monitoring, noise protection, waste avoidance and protection of soil and ground water.

In addition, the company's product range includes a great number of valves designed to use water sparingly on an on-going basis.

Anfahrt

Anfahrt

In the middle of Europe

Flühs Drehtechnik is located in the heart of Europe. With quick connections to many European countries, it guarantees a productive workflow and a contemporary delivery.

How to find us

Flühs Drehtechnik is located close to the motorways A45 and A4 the main routes, which connect the Frankfurt/Main area and the Ruhr area.

By clicking our logo on the map below you will be re-directed to Google Maps. There you can simply enter your address and will get the respective directions.

Flühs equipped

Flühs equipped

The “Flühs equipped” logo has been developed as a marketing tool for those customers who use Flühs products.

The well established and famous brand Flühs indicates and stands for highest quality valve technology for decades.

Procedure to receive the logo:

1. Our “Flühs equipped” logo is a registered trademark and can be used only for one calendar year. It has to be renewed with our assistance after one year’s period.

2. You will receive a vector graphics file (AI or EPS format) bearing the name of your company and the year of duration.

3. The logo can be used for catalogues, packings, flyers, as well as stickers (e.g. on the faucet) etc. and only for those products assembled with Flühs cartridges.

For the right marketing tool of your company please contact us.

info@fluehs.de